What’s one of the most important systems on your vehicle? While it’s easy to make a case for several, moving the brake system towards the top of the list is apparent. Imagine sailing down the highway after a day of skiing, only to find your brakes no longer work. That would be a scary experience at best.

Yet a lot can happen to the brake system between being brand new and complete failure. Worn brakes occur after a lot of miles put on your car. It happens over time. And as the miles add up, your brakes deteriorate, they don’t work quite the way they do when they were new.

They also start providing telltale signs they are wearing down. Notice the warning signs and you can fix your brakes long before they present you with a problem.

Understanding the brake system

Before we get into the many ways you’ll start to notice worn brakes, it’s important to understand how a car’s brake system works.

If you’ve ever ridden a bicycle, you have a basic understanding of how a brake system works. A bike has two wheels, with a brake attached to both. To control the speed, you press down on a hand brake, which applies pressure to each wheel and slows it down. The harder you push, the more force is used until eventually, the bike comes to a complete stop.

The same applies to a vehicle, using four wheels instead. Cars have brakes on all four wheels, which is operated through a hydraulic system to make it easy to stop without a lot of work on your part.

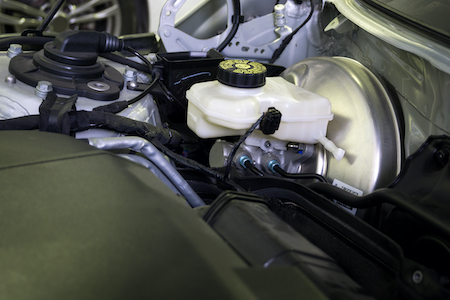

When your foot pushes down on the brake pedal, hydraulic force is sent into the system to start the braking process. A piston moves into a cylinder and squeezes hydraulic fluid into the braking system. It moves through a series of brake lines and hoses to lubricate and produce a reaction. Pressure is transmitted to all four brake lines, which forces friction between the brake rotors and brake pads. As this pressure continues, it slows the vehicle until it eventually comes to a full stop.

If any piece of this process starts to wear, it impacts the drive of your car.

Of course, some are more noticeable than others. What can happen if you continue to drive with worn brakes?

You can experience unpleasant sounds and smells

There’s no ignoring worn brakes. That’s by design. One of the most common repairs within the brake system is to replace worn out brake pads. Manufacturers design brake pads with a warning signal built in. As you get towards the end of the brake pad, metal is revealed which, when it connects with the brake rotor, will create a loud squealing sound.

You might also notice a burning smell. If your brakes are new, that burning smell might simply be the resin used in production burning away as the brakes settle in. But if you’ve been driving for a while and you start to notice a burning smell, it can be from other complications. Brake fluid leaking can settle onto the brake pads, and when it’s heated from the friction of stopping, it can produce a burning smell. This is where it pays to know your car well.

You can feel your car vibrate as you brake

When your vehicle is working properly, every process works smoothly. When you tap on the brakes, your vehicle slows until eventually coming to a stop.

But when your brake pads have excessive wear or are damaged in any way, they don’t make a solid connection with the rotors. And without a solid connection, it can trigger an on-off connection, meaning you’ll feel a vibration as it works its way up through the system.

If the car shakes or you feel vibrations through the steering wheel as you apply the brakes, and it stops as you take your foot back off the brake pedal, there’s a good chance it’s time to have your brakes serviced.

You notice it takes longer for your car to come to a complete stop

Remember when your brakes were new? You tapped on the brake pedal and it felt like your car could stop on a dime?

Over the years, you have to apply more pressure to get the same reaction. It’s essential to pay attention to response time. How much give is there as you press on the brake pedal? Do you feel your vehicle slowing with a tap, or are you having to press it all the way down?

If you don’t have as much control through pushing on the brake pedal, it can slow your reaction time, putting you in more danger. If they don’t engage or disengage, the pads aren’t gripping properly or uniformly, which impacts how well you control your car. This can put you in a variety of dangerous positions, especially if you add inclement weather into the mix too.

You notice your tires wearing down

Your tires are one of the most important parts of the brake system. They are what connects your vehicle to the road. Without the proper tire pressure and tread levels, they won’t have gripping power. And that can mean putting you at risk as you drive.

You can do a few things to check your tires. Check the tire pressure at least once a month, more as we move through heatwaves and cold spells. If your car doesn’t have a tire pressure gauge built in, you can check it regularly at your local service station.

You should also do a visual test regularly. Before getting in and driving away, walk around your vehicle and inspect your tires. Is one flatter than the others? Do you see any signs of damage? The faster you take action on potential problems, the better chance you have of fixing it before it needs full replacement.

Keep an eye on tread levels as well. You can do this easily with a penny test. Place a penny with Lincoln’s head upside down and facing you into the tread of the shallowest part of the tire. If you can see the top of his head, your tires have worn down and need to be replaced.

Can you drive on worn brakes? You do so every day. But when they reach a point of putting you, your passengers, and others around you at risk, it’s time to take action.

Brakes that work properly are essential to your safety. You want to carefully maintain your brakes. In vehicles that are equipped with drum brakes, the brake components are housed inside a drum that rotates with the wheel. When you step on the brake pedal, brake shoes push out against the inside of the drum, slowing the wheel.

Brakes that work properly are essential to your safety. You want to carefully maintain your brakes. In vehicles that are equipped with drum brakes, the brake components are housed inside a drum that rotates with the wheel. When you step on the brake pedal, brake shoes push out against the inside of the drum, slowing the wheel. While these are the main components of the braking system, there are many more parts that go into making up each individual component. If any of these parts wear down, break, or leak, it can put your braking system in jeopardy.

While these are the main components of the braking system, there are many more parts that go into making up each individual component. If any of these parts wear down, break, or leak, it can put your braking system in jeopardy. Your vehicle’s brakes are designed to bring your car to a stop. The more pressure you apply to the brake pedal, the more tension is transferred from the brake pad to the wheel, slowing your car until it eventually stops.

Your vehicle’s brakes are designed to bring your car to a stop. The more pressure you apply to the brake pedal, the more tension is transferred from the brake pad to the wheel, slowing your car until it eventually stops. ABS icon lights up

ABS icon lights up Like brake pads, brake shoes are made from organic and metallic materials, tough enough to survive the friction required for the braking process. These materials are bonded together to keep them from shedding or breaking under intense heat and pressure. This material is packed into the brake shoe, and is created to fit precisely within the brake drum as well as the contact surface of the cylinder pistons.

Like brake pads, brake shoes are made from organic and metallic materials, tough enough to survive the friction required for the braking process. These materials are bonded together to keep them from shedding or breaking under intense heat and pressure. This material is packed into the brake shoe, and is created to fit precisely within the brake drum as well as the contact surface of the cylinder pistons. A small pickup will have gross weight of anywhere from 5,000 to 7,000 pounds. If you have a heavy duty pickup, gross weight can move up to 7,000 to 12,000 pounds. While manufacturer specs are needed to properly define actual weight, in any case you move a lot of mass around every time you sit behind the wheel.

A small pickup will have gross weight of anywhere from 5,000 to 7,000 pounds. If you have a heavy duty pickup, gross weight can move up to 7,000 to 12,000 pounds. While manufacturer specs are needed to properly define actual weight, in any case you move a lot of mass around every time you sit behind the wheel. The brake system moves into action as you step on the brake pedal. Through hydraulics, the force of the brake pedal moves pressurized brake fluid through the line, down into the caliper. The caliper then squeezes the

The brake system moves into action as you step on the brake pedal. Through hydraulics, the force of the brake pedal moves pressurized brake fluid through the line, down into the caliper. The caliper then squeezes the

With a disc brake system, a disc turns the wheel. The disc is straddled by a brake caliper, which is controlled by pistons operating from the master cylinder. These pistons press against brake pads that case friction and stop the vehicle. These pads are shaped to cover a significant portion of the rotor, to ensure it properly stops the car.

With a disc brake system, a disc turns the wheel. The disc is straddled by a brake caliper, which is controlled by pistons operating from the master cylinder. These pistons press against brake pads that case friction and stop the vehicle. These pads are shaped to cover a significant portion of the rotor, to ensure it properly stops the car.