Every part on your vehicle is under pressure as you drive. Few parts, however, experience the daily bumps and grinds quite the way your wheels do.

Imagine the pressure placed on the wheels as you hit one of the infamous potholes that form over the long winter months here along the Front Range.

Or how about the way your wheels bounce and move when you take a dirt road?

Or even when your car touches the curb as you slide on ice buildup from the latest storm?

That bent wheel is telling you something. You may even feel it in the way your car drives.

Should you replace the damaged wheel? Should you repair it? Ignore it?

What are wheels made of?

The majority of wheels placed on vehicles today are made of cast aluminum alloy. They are created by pouring molten aluminum into a mold. This creates a lightweight yet strong product that, in general, works better than steel wheels used in the past. Because of how they are poured, they can take on many different looks and sizes, making them a popular choice for today’s vehicles.

The wheel is the structure surrounded and protected by the tire. The wheel has a center cap that sits in the middle, with a center bore in the back. They have lug holes where bolts are used to keep everything in place. You also have spokes, which connect the center of the wheel with the outer rim of the wheel. This is where the decorative part of your wheel exists. Finally, wheels also have an outer lip, a valve stem, and the barrel. Together, they create a wheel that holds up under all kinds of pressure.

The wheel is the structure surrounded and protected by the tire. The wheel has a center cap that sits in the middle, with a center bore in the back. They have lug holes where bolts are used to keep everything in place. You also have spokes, which connect the center of the wheel with the outer rim of the wheel. This is where the decorative part of your wheel exists. Finally, wheels also have an outer lip, a valve stem, and the barrel. Together, they create a wheel that holds up under all kinds of pressure.

Without a stable wheel, the tire can’t operate at peak performance. They work well when both are properly maintained. If any of the elements are damaged or not in optimal working condition, it’s important to get them repaired as quickly as possible, or replaced if they can’t be fixed.

What causes wheel damage

Wouldn’t it be nice if you knew exactly what would cause damage to your wheels so you could avoid it? While there are a lot of variables in what can impact the wheels, there are a few guidelines that can help you become a more aware driver.

Driving on a flat tire – Have you ever watched a pilot walk around the plane before taking off doing a flight check? As a driver, you should have your own routine in place. As you walk up to your vehicle, glance at the tires – is one of them low on air, even flat? If your tire isn’t up for the job of protecting the wheel, it’s more likely the wheel will experience damage as you drive. Tires are designed to absorb the impact. They can’t do that if they aren’t in optimal condition. That means you should check tire pressure periodically and replace them before they further put your vehicle at risk.

Hitting a curb – how many times have you mistaken a driveway for a curb? You can tell when your car clunks and drops that the drop was larger than anticipated. Or maybe you turn a little too quickly and tap the curb as you’re turning a corner. We all do it. But that can also be a big problem for your wheels. The best course of action is to slow down and pay attention to where your car is moving.

Winter roads – sometimes bumps and dips in the road aren’t the only things to cause damage. Every winter, our roads are in constant flux with mag-chloride being sprayed on, sand and gravel laid into place, and ice and snow impacting our drive. Driving through these chemicals and other pollutants can cause a buildup on the rims. Over time, depending on the metal alloy, these corrosive materials can eat away at the structure of the wheel until they break the seal with the tires. That’s a good reason to clean your vehicle frequently during the winter months to keep your car clean of these chemicals.

Be conscious of parking – if you frequently parallel park, how often do you touch the curb with your wheels? Do you bounce off the curb in front of you as you park in a lot? This constant scrape can wear down both your tires and your wheels until it causes serious damage.

Driving on rough pavement – sometimes there is no way to avoid rough pavement. And here in Colorado, the condition of the pavement changes all the time. Huge cracks sometimes seem to form overnight. Pop-up parking lots can have you traveling over gravel and stone. Have you ever followed Siri’s instructions and found yourself on rough, unknown roads? All of this can be hard on the rims, especially if your tires are weakened.

Hitting potholes – one of the biggest causes of wheel damage is potholes, something we get quite a lot of here, thanks to our winter conditions. You know the moment you hit one that your car has suffered from the impact. Even though you cringe when you hit one, it depends on the severity your wheels take the impact. Rough edges and the depth of the hole can all add into how much damage it sustains. If you suspect a problem, or notice a difference in the way your car drives, it’s time to schedule a check-up.

Replace or repair?

Wheels are built tough and should take quite a bit of impact as you drive. It all depends on the driving conditions, and how well your vehicle is maintained.

If you suspect an issue, don’t wait. Problems escalate quickly, and what started out as a simple repair suddenly turns into a major expense. A problem with your wheels could further jeopardize your tires, the brake system, or the suspension system. And as more repair work is needed, costs quickly follow.

Our team here at Express Car Care is ready to answer all of your questions, and get you back on the road as quickly as possible.

How can we help you?

Your radiator hoses carry coolant between your engine and radiator. It’s an important job. If a radiator hose fails, you could lose your engine coolant which might lead to overheating and very expensive engine damage, so you always want to make sure you have good hoses.

Your radiator hoses carry coolant between your engine and radiator. It’s an important job. If a radiator hose fails, you could lose your engine coolant which might lead to overheating and very expensive engine damage, so you always want to make sure you have good hoses. A manual transmission relies on you to operate the clutch and shift as needed.

A manual transmission relies on you to operate the clutch and shift as needed. The rack is linear rather than round. It’s long and flat with prongs on one side. The rack is attached to the steering column by a series of tie rods.

The rack is linear rather than round. It’s long and flat with prongs on one side. The rack is attached to the steering column by a series of tie rods. If you’ve put money into repairing it before small fixes turn into larger problems, it might be worth fixing a few car dings, or even repainting your car. It can make you feel happier when you walk up to your car in the parking lot, and drive it on the city roads. It can even add to the value, becoming something someone else wants to drive rather than an eyesore they hide from their friends.

If you’ve put money into repairing it before small fixes turn into larger problems, it might be worth fixing a few car dings, or even repainting your car. It can make you feel happier when you walk up to your car in the parking lot, and drive it on the city roads. It can even add to the value, becoming something someone else wants to drive rather than an eyesore they hide from their friends. The head gasket has an important job to ensure your vehicle operates smoothly. When your head gasket is blown, it means one or more of these fluids or gases are going where they shouldn’t be.

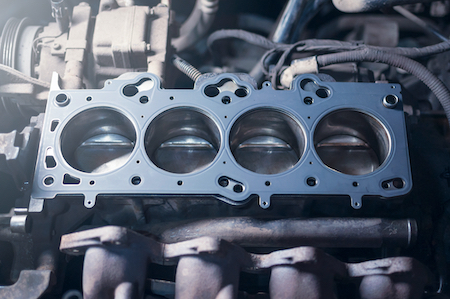

The head gasket has an important job to ensure your vehicle operates smoothly. When your head gasket is blown, it means one or more of these fluids or gases are going where they shouldn’t be. Big advances in automotive technology have led to the development of high-tech fluids to keep pace. A simple example of this is the cooling system. For decades it was primarily made out of iron, steel and rubber hoses. There was one kind of coolant that protected these components from corrosion.

Big advances in automotive technology have led to the development of high-tech fluids to keep pace. A simple example of this is the cooling system. For decades it was primarily made out of iron, steel and rubber hoses. There was one kind of coolant that protected these components from corrosion. In general, you’ll often see commercials talk about both

In general, you’ll often see commercials talk about both  One trip to the auto parts store will tell you there are dozens – hundreds – of

One trip to the auto parts store will tell you there are dozens – hundreds – of  An oil change is one of the most basic services your pickup truck needs. It used to be that vehicles needed

An oil change is one of the most basic services your pickup truck needs. It used to be that vehicles needed